Embarking on a robotics project is an exciting venture, but one of the crucial decisions you'll face is selecting the right motor driver. The motor driver acts as the bridge between your microcontroller and the motors, controlling their operation and ensuring they perform as intended. With a plethora of options available, choosing the appropriate motor driver can be daunting. This guide will walk you through the essential factors to consider to make an informed decision.

Understanding Motor Drivers

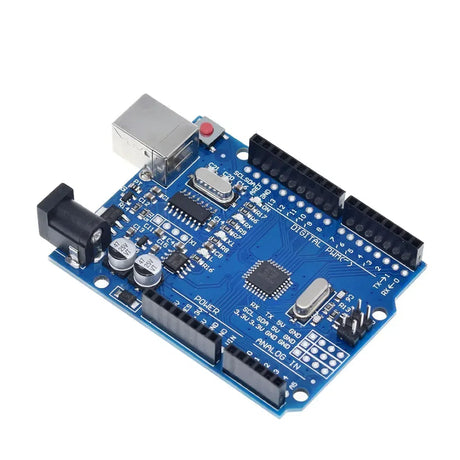

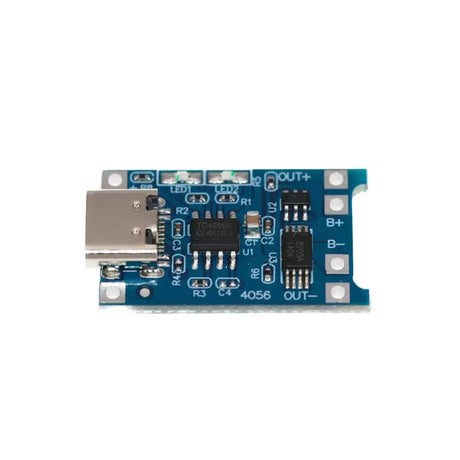

A motor driver is an electronic device that interfaces between a microcontroller (like an Arduino or Raspberry Pi) and a motor. It handles the high power requirements of motors, providing necessary voltage and current while allowing precise control over motor operations such as speed and direction. Motor drivers come in various types, each suited for specific applications and motor types.

Factors to Consider When Choosing a Motor Driver

1. Motor Type

Different motor types require different drivers. The most common types include:

- DC Motors: Simple and widely used; require basic H-bridge drivers for speed and direction control.

- Stepper Motors: Require precise control of steps; need specialized stepper motor drivers that manage microstepping and current control.

- Servo Motors: Often controlled by PWM signals; sometimes integrated into more complex drivers.

2. Voltage and Current Requirements

Assess the voltage and current ratings of your motors. Ensure the motor driver can handle the required voltage and provide sufficient current without overheating. Exceeding the driver's ratings can damage both the driver and the motors.

3. Control Interface

The motor driver should be compatible with your microcontroller's control interface. Common interfaces include:

- PWM: For speed control via pulse-width modulation.

- Serial: For communication over protocols like SPI or I2C.

- Analog: For variable control signals.

4. Number of Motors

Determine how many motors you need to control. Some motor drivers can handle multiple motors simultaneously, which can simplify your design and reduce the number of components.

5. Features

Look for additional features that may benefit your project:

- Speed Control: Ability to adjust motor speed smoothly.

- Direction Control: Easily change motor rotation direction.

- Braking: Enables quick stops and precise positioning.

- Protection Features: Overcurrent, overvoltage, and thermal protection to safeguard your components.

6. Size and Form Factor

Consider the physical dimensions of the motor driver. Ensure it fits within your project's space constraints, especially for compact or portable robots.

7. Compatibility with Microcontroller

Ensure the motor driver can be easily integrated with your chosen microcontroller. Check for available libraries and community support, which can simplify the development process.

8. Cost and Availability

Balance your budget with the features you need. Sometimes, investing in a more expensive driver with additional features can save time and improve performance. Also, ensure that the driver is readily available for future projects or replacements.

Common Types of Motor Drivers

Here are some common types of motor drivers used in robotics:

- L298N: A dual H-bridge driver suitable for driving two DC motors or one stepper motor. It's affordable and widely used in hobby projects.

- DRV8825: A stepper motor driver with microstepping capabilities, providing finer control over motor movements.

- TB6612FNG: A compact dual motor driver with higher efficiency than L298N, supporting DC and stepper motors.

- Pololu Motor Drivers: A range of drivers offering various features and current capacities, suitable for different applications.

Examples of Popular Motor Drivers

L298N Dual H-Bridge Motor Driver

The L298N is a popular choice for beginners due to its simplicity and availability. It can control two DC motors or one stepper motor and handle up to 2A per channel.

// Example: Controlling a DC motor with L298N and Arduino

const int IN1 = 8;

const int IN2 = 9;

const int ENA = 10;

void setup() {

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

}

void loop() {

// Move forward

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

analogWrite(ENA, 200); // Speed control via PWM

delay(2000);

// Move backward

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

analogWrite(ENA, 200);

delay(2000);

// Stop

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

delay(1000);

}

DRV8825 Stepper Motor Driver

The DRV8825 is ideal for projects requiring precise stepper motor control. It supports up to 1.5A per coil and offers microstepping for smoother operation.

// Example: Controlling a stepper motor with DRV8825 and Arduino

#include

const int stepsPerRevolution = 200;

Stepper myStepper(stepsPerRevolution, 8, 9, 10, 11);

void setup() {

myStepper.setSpeed(60); // 60 RPM

}

void loop() {

myStepper.step(stepsPerRevolution);

delay(1000);

myStepper.step(-stepsPerRevolution);

delay(1000);

}

Conclusion

Choosing the right motor driver is critical for the success of your robotics project. By carefully evaluating your motor type, voltage and current requirements, control interface, and other key factors, you can select a motor driver that not only meets your project's needs but also enhances its performance and reliability. Whether you're a hobbyist or a professional, understanding the nuances of motor drivers will empower you to build more efficient and effective robotic systems.