Számítsa ki a 3D nyomtatás költségeit az anyag súlya, a nyomtatási idő és a további tényezők, például az elektromos áram, a munkaerő és a nyomtató teljesítménye alapján.

3D nyomtatási költségszámológép

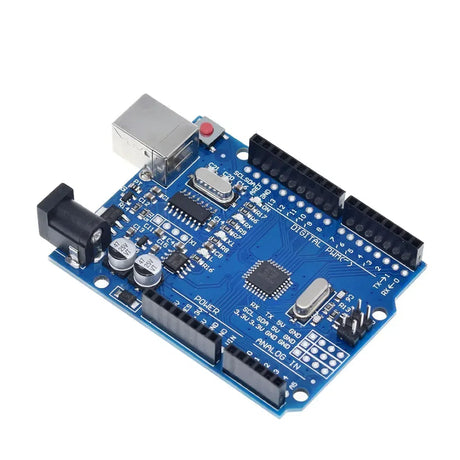

3D printing has revolutionized the way we approach manufacturing, prototyping, and creative projects. Whether you're a hobbyist crafting intricate models or a business developing prototypes, understanding the costs involved in 3D printing is essential for effective budgeting and project planning. Accurately estimating these expenses ensures that your projects stay within financial limits while achieving the desired quality and complexity.

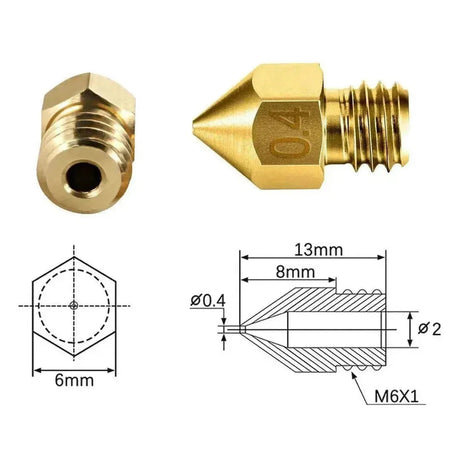

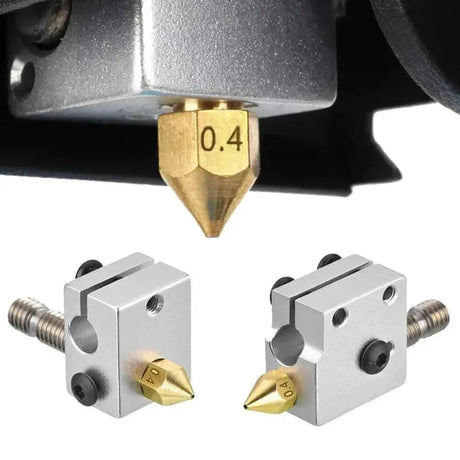

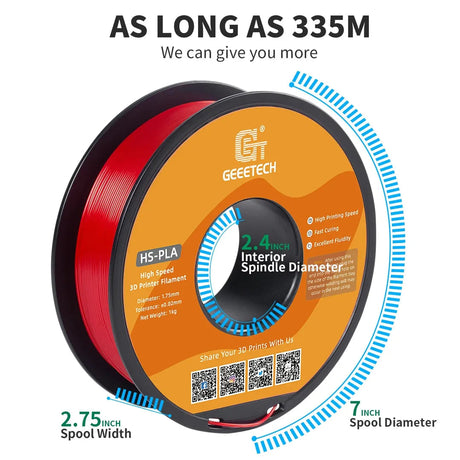

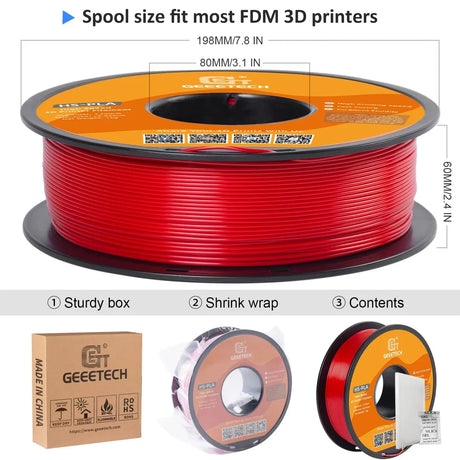

One of the primary factors influencing the cost of 3D printing is the material used. Different materials, such as PLA, ABS, or resin, vary in price per gram, and the total material cost directly depends on the weight required for your specific project. Additionally, the weight of the material impacts not only the cost but also the structural integrity and functionality of the printed object. By calculating the material cost based on weight, you can make informed decisions about the best materials to use for your needs.

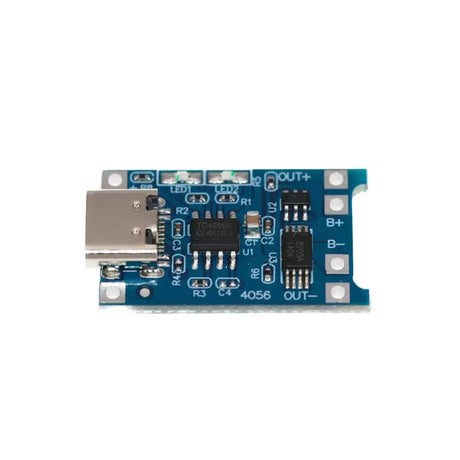

Printing time is another critical component in determining the overall cost of a 3D print. Longer printing times consume more electricity and may require higher printer power settings, which can significantly increase expenses. Understanding how printing time affects your budget allows you to optimize print settings for efficiency without compromising the quality of the final product. This balance is particularly important for large-scale projects or when working with tight deadlines.

Electricity and labor costs also play a significant role in the total cost calculation. The energy consumed by the 3D printer during operation contributes to the overall expense, especially if the printer operates for extended periods. Additionally, the cost of labor, whether it's your own time managing the printer or hiring skilled technicians, adds to the financial considerations of a project. By factoring in electricity and labor costs, you gain a comprehensive view of all expenses involved in the 3D printing process.

Utilizing a 3D print cost calculator can streamline the budgeting process by providing a detailed breakdown of all associated costs. This tool allows you to input various parameters, such as material cost per gram, material weight, printing time, printer power, electricity cost per kWh, labor cost per hour, and labor hours, to generate an accurate total cost estimate. With this information at your fingertips, you can plan your projects more effectively, allocate resources wisely, and ensure that your 3D printing endeavors are both financially viable and successful.

Understanding the nuances of 3D printing costs empowers creators and businesses alike to optimize their workflows and make strategic decisions. Whether you're experimenting with new designs or scaling up production, having a clear grasp of the financial aspects helps in achieving your goals efficiently. By leveraging detailed cost calculations, you can navigate the complexities of 3D printing with confidence and creativity.

3D Printing & Costing

- 3D Print Cost Calculator – Calculate the cost of 3D printing, including material, electricity, and labor.

- Print Time Estimator – Estimate how long a 3D print will take based on layer height, speed, volume, and infill percentage.

Notice an Issue? Have a Suggestion?

If you encounter a problem or have an idea for a new feature, let us know!

Report a problem or request a feature here.